Traceability

Customers need to be able to monitor the performance of individual modules as well as the larger machine of which they are a part. This becomes particularly important when usage is a mix of new buy and remanufactured product.

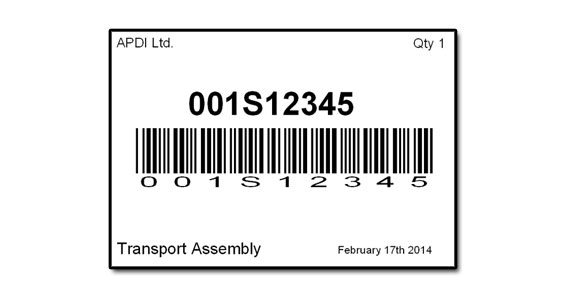

At APDI each module is uniquely identified providing traceability back to the date, the operator, the final test station operator and materials used. Enabling us to determine how many Remanufacturing cycles the module has been subjected to, helping to identify the level of future remanufacturing required.

Our Mission and Principles

Our Mission and Principles

of Remanufacturing

Our Mission is to be regarded as experts in the re-manufacture of electro-mechanical modules/ assemblies. Click a segment for more details.

Learn the module application and customer expectations. Understand the module design and component functionality.

Learn the failure modes- Critical to know the reman process will capture all failure causes. Develop re-use criteria for all components.

Ensure capability of new materials. OE materials/components preferred. Rigorous field trials. In-house testing to ensure functionality and life.

Understand assembly requirements and settings- dedicated tooling and fixtures to provide capability. Fully trained workforce participating in the development of the process and FMEA’s. Robust final inspection. 100% machine test often used. Continual improvement as process matures. Build team involvement.

Work closely with customers’ & supply chain from design through manufacture to field support specialists.